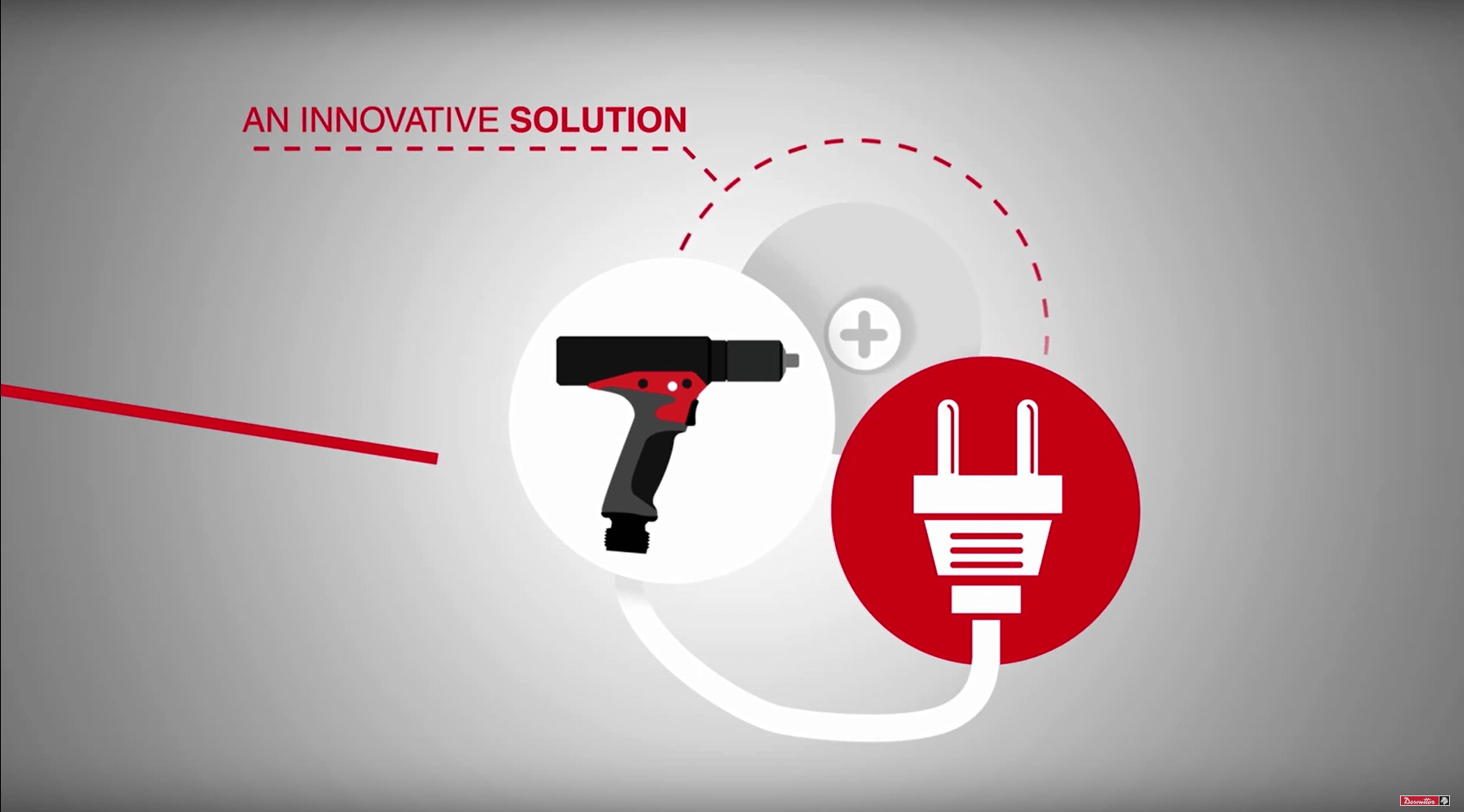

The E-PULSE is the first fully electric pulse tool on the market that offers a complete transformation from pneumatic to electric reaction-free assembling tooling.

The flexibility of modern automotive assembly plants is a sight to behold. These days, it’s not uncommon to see completely different car models being produced on the same production line, with absolutely no delay.

That sort of adaptability requires the seamless integration of advanced robotic systems. Just as crucially, it also calls for assembly line workers to perform their tasks in the most efficient and productive manner possible.

These demands are driving the uptake of new handheld tools across the automotive sector. An example of this is the E-PULSE Low Torque Reaction Electric Tool, already adopted by a number of manufacturers including Toyota and Hyundai, which features a patented pulse mechanism meaning that the tool gives no torque reaction to the operator.