In today’s fast-paced manufacturing environment, the ability to collect and analyse data efficiently is crucial for maintaining a competitive edge. Production line managers are increasingly turning to advanced data collection and analysis solutions to streamline operations, reduce downtime, and improve overall productivity.

电动出行

通用行业

汽车装配

航空航天

Revolutionising production lines with data collection and analysis

December 9, 2024

Continuous Improvement and Optimisation

| Data plays a pivotal role in continuously improving and optimising tightening and drilling manufacturing processes. Companies strive to be agile, producing a variety of products and needing real-time data to ensure processes are optimised for the best results. This agility is essential for maintaining high standards and achieving production goals. |

| Ready to optimise your production processes? Contact us today to learn how our solutions can help! |

|

|

"Every second counts and data helps! Our world is changing fast, and our industry must constantly adapt to meet environmental and economic challenges. |

|

|

|

||

|

Sebastien Lebret - Product Marketing Manager |

Enhancing Error Proofing

|

| Data significantly impacts the error proofing process. Accurate data from tools enables companies to make swift, informed decisions. This data indicates whether a product meets the required standards, and if not, it guides the next steps.Automation of decisions in the error proofing process ensures errors are promptly addressed, maintaining product quality and reducing waste. Perhaps you need: |

|

|

Data-driven solutions can help in this process. |

|

|

|

Discover how our error proofing solutions can enhance your production line. |

Ensuring Product Traceability

|

|

Product traceability is another critical application of data in manufacturing. Data helps verify that products are built with the correct materials, following the right tightening processes, and by properly trained personnel. It also ensures that products are made correctly even after leavin g the facility. This traceability is crucial for quality control and addressing any post-production issues. |

|

|

|

Ensure complete traceability in your production line.

Schedule a demo with us today!

Real-World Examples:

Automotive and General Industry

|

| In the automotive industry, digitalization has become indispensable. For instance, advanced data analysis and machine learning can help Original Equipment Manufacturers (OEMs) build safer vehicles and avoid costly recalls by analysing continuously the tightening curves of the critical operations under various conditions. This proactive approach improves the quality of the production such as airbags or engines. It can prevent issues before they escalate, saving both time and resources. |

| Another usage in General Industry for high precision equipment, consists of using AI to classify results to identify the factors which could have influence on the quality of your production. It contributes actively to the continuous improvement of the production process. |

|

Learn more about how data analytics can transform your industry. Explore our solutions! |

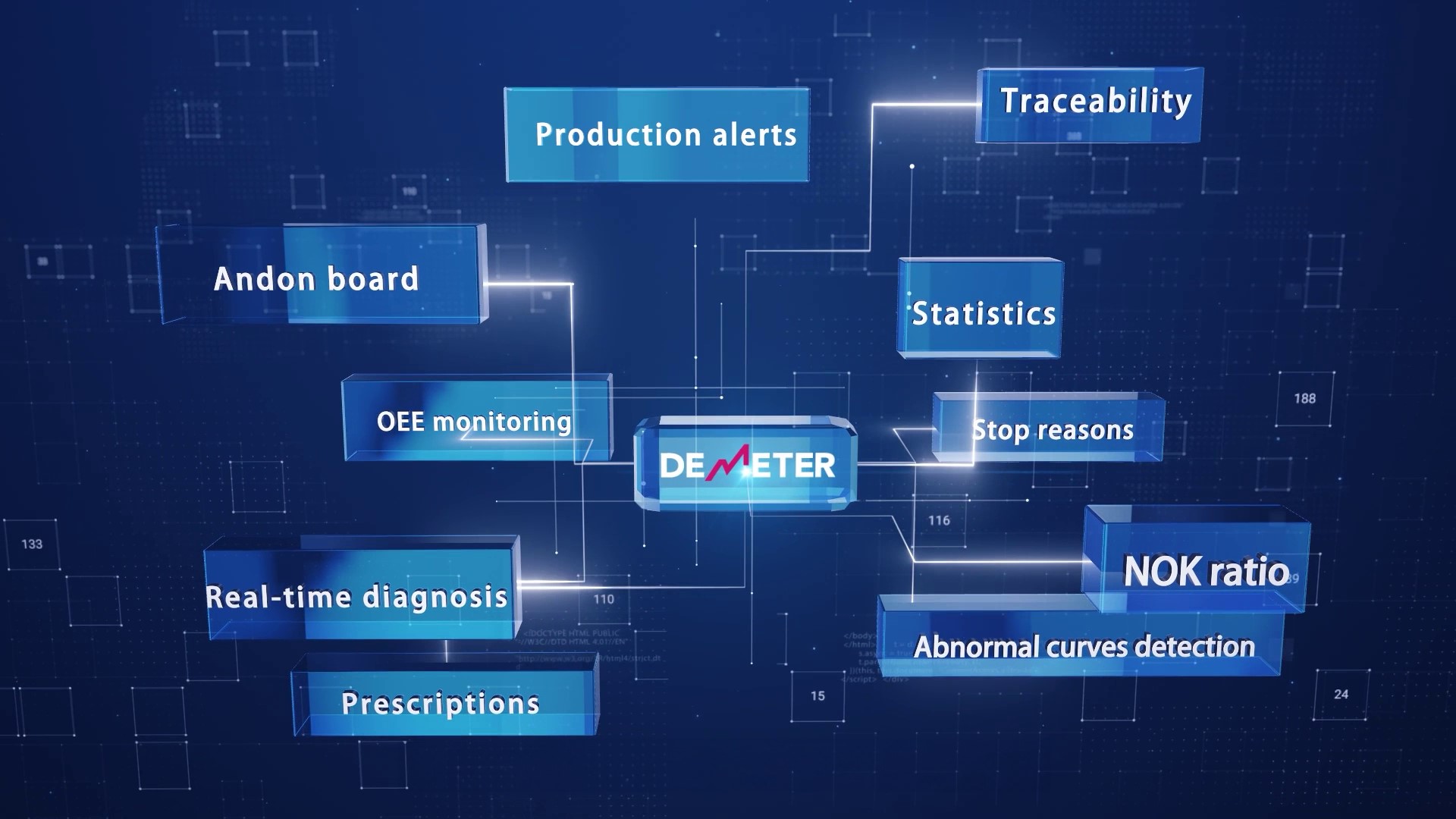

Desoutter's DeMeter Solution

|

| Desoutter provides a comprehensive solution to these challenges with its Demeter software. Demeter automates the collation, processing, and analysis of production data from Desoutter smart tools and other sources. This powerful tool allows production line managers to monitor their operations in real-time, providing an intuitive live dashboard that tracks every aspect of production. By using Demeter, you can make informed decisions on the spot, ensuring your production line is always running at peak efficiency. |

|

|

|

Start optimising your production line with DeMeter. Request a free assessment today! |

Conclusion

| These are just a few ways that digitalisation and AI are transforming manufacturing processes. By leveraging these solutions, production line managers can ensure their operations are efficient, agile, and capable of meeting high-quality standards. Embracing data-driven decision-making is key to staying competitive in the modern manufacturing landscape. Desoutter’s Demeter solution is here to help you achieve these goals, providing the tools you need to optimise your production line. |

Discover DeMeter

DeMeter helps you with prescriptions to continuously improve your productivity and your quality