Aumentate la produttività e mantenetevi all'avanguardia con la nostra Guida alla produzione intelligente nella vostra linea di assemblaggio.

Scopri le strategie per i processi basati sui dati, la tracciabilità totale, la gestione efficiente degli utensili, l'automazione leggera e altro ancora. Esplorate l'ECOSISTEMA di Desoutter per trovare soluzioni esperte.

Aumentare la produttività e lavorare in modo più intelligente è fondamentale per mantenere un vantaggio competitivo. L'introduzione di processi di smart manufacturing che si evolvono nel tempo con l'azienda può garantire l'agilità necessaria per riequilibrare i processi produttivi in risposta alle fluttuazioni del mercato e la flessibilità necessaria per adottare rapidamente nuove tecnologie e implementare modalità di lavoro migliori. L'Industria 4.0 definisce i principi della produzione intelligente, ma trasformare la teoria in realtà in un ambiente di produzione impegnativo può essere una sfida. I produttori hanno bisogno di modi pratici per sfruttare e applicare il potenziale dell'Industria 4.0 per migliorare l'efficienza operativa, eliminare le rilavorazioni e migliorare i margini. Ciò include la capacità di pianificare, progettare e migliorare continuamente i singoli processi in qualsiasi momento.

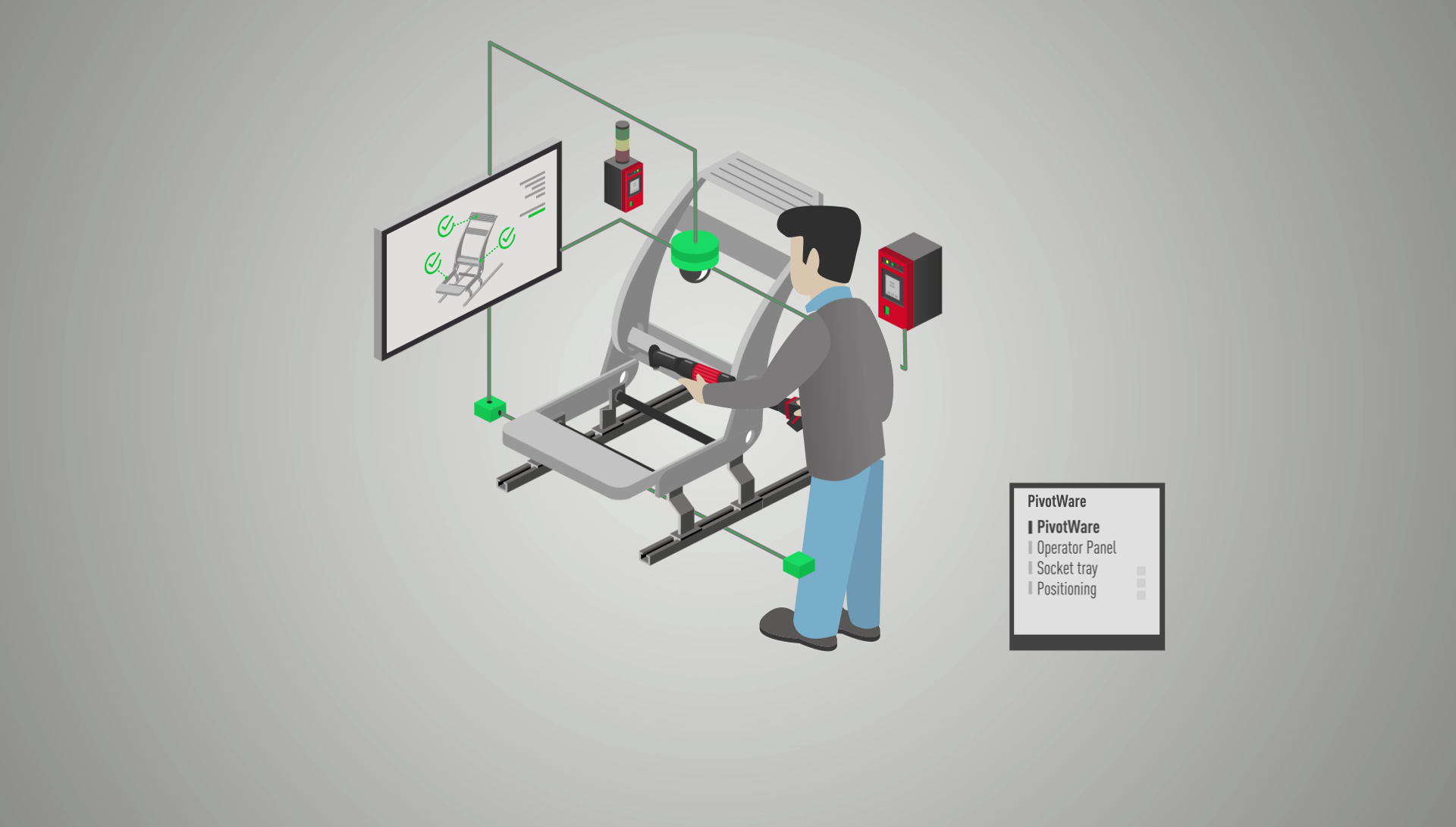

In che modo è possibile applicare la connettività (IoT), l'Internet delle cose, l'estrazione dei dati e l'integrazione continua per ottenere grandi vantaggi per la vostra azienda? La chiave è costruire gradualmente, fino ad avere un ecosistema di produzione intelligente che comprenda tutto, dagli strumenti di assemblaggio intelligenti alla potente analisi dei dati.

Ecco i principali consigli di Desoutter’per sviluppare linee di assemblaggio intelligenti che siano scalabili, adattabili e a prova di futuro.