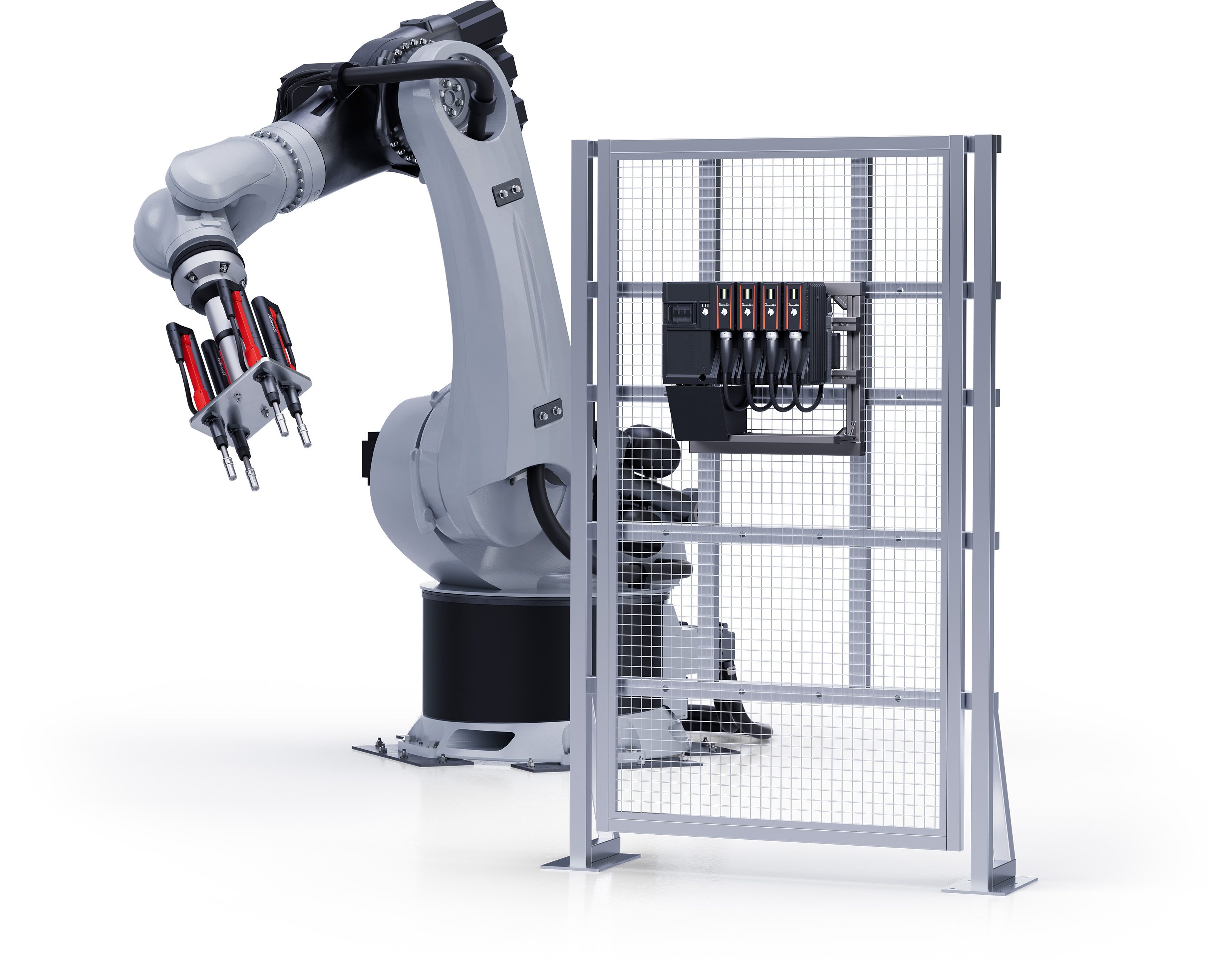

Discover the Desoutter MULTI, Modular Multi-spindle solution, for high performance, multi-spindle applications. Desoutter has developed the MULTI to help customers boost productivity while reducing downtime and total cost of ownership (TCO).

A smart multi-spindle solution that achieves changeovers in less than 30 seconds, unaffected by environmental conditions at any torque level or takt time. A solution which delivers consistent tightening without the need for special training and has inbuilt preprogrammed corrective maintenance features scenarios.