Insulated Tools for EV Battery Manufacturing: Safeguarding Workers and Enhancing Productivity

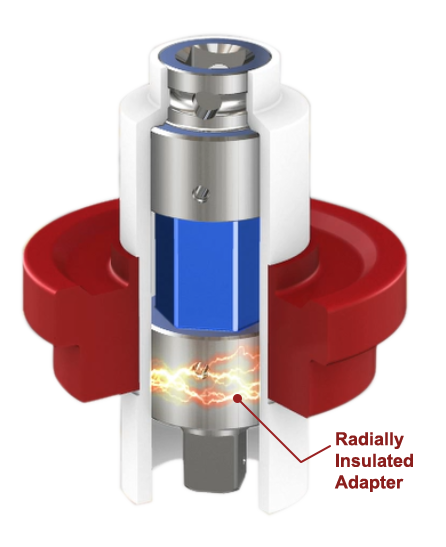

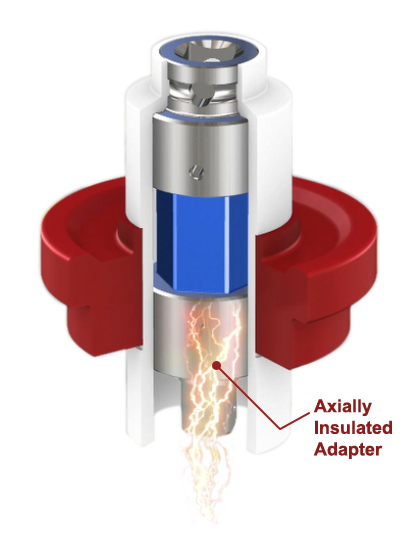

Electric vehicles (EVs) are quickly growing in popularity as consumers and governments alike become more environmentally conscious. Lithium-ion batteries power most EVs, which creates a unique set of challenges in their manufacturing. The batteries come pre-assembled and pre-charged, which exposes workers to high voltage and increases the risk of accidents. That’s where insulated tools and covers come in to reduce the danger and protect the manufacturing process. Smoke and fire from Li-ion batteries can be damaging to the rest of the production and the people surrounding it. In this article, learn how electric insulated tools can prevent shock from high voltage and ensure safe and efficient assembly of electric vehicles, and why not all insulated tools are created equal.