Insulated Hand Protection:

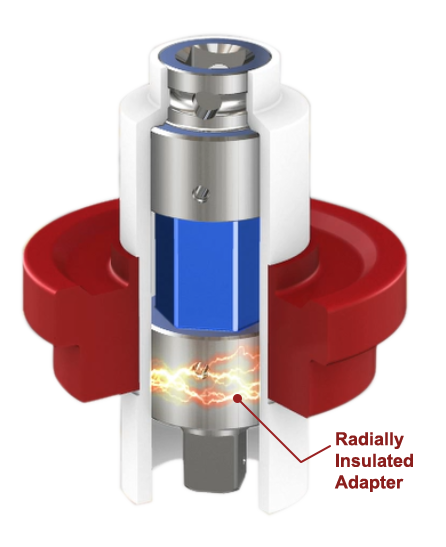

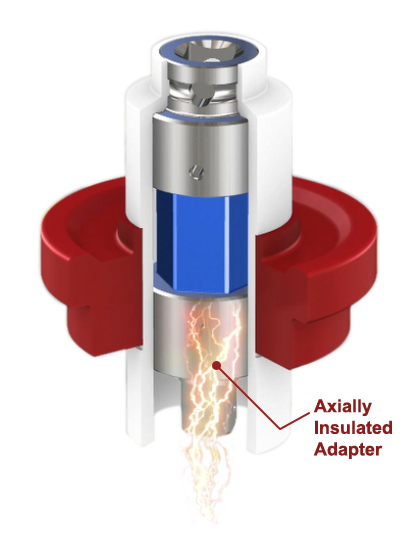

To minimize the risk of accidents and electrical hazards during the assembly process, it is strongly advised to use hand protection measures. These precautions help prevent accidental slips from the tool end and unintended contact with the battery pack. Additionally, keeping hands away from exposed electrical components, whether through direct contact or arcing, is crucial. Incorporating this extra safety measure is highly recommended to enhance overall safety during assembly.

“Hand protection can be removed based on the risk analysis conducted by the customer at their station, in case the application requires non-hand-held tools or if the operator wears electrical safety gloves.”

- Desoutter Tightening Expert

|

|

|

It is of utmost importance to prioritize solutions that adhere strictly to international norms to ensure the safety and reliability of your projects, workers, and equipment. Compliance with IEC 60900:2018 and IEC 60664-1:2020 is essential, as it guarantees operator protection for currents below 1000V/AC and 1500V/DC. Look for products that have been thoroughly tested and approved by reputable organizations such as DEKRA. By prioritizing adherence to these norms, you can have the confidence that your tools and equipment meet the necessary standards for safety and reliability. Additionally, these solutions can be designed to be compatible with various software and can be seamlessly integrated with different set-up, minimizing the risk of errors through features like video positioning, for example.