Genel Endüstri

Havacılık ve Uzay

E-Mobilite

Otomotiv

Taking quality control in torque management to a new level! Discover WRT

June 17, 2024

Automotive assembly is a complex process, often involving multiple tools that require regular calibration and verification to maintain quality standards and ensure that critical fasteners are properly tightened.

Closely allied to quality control is the need for total traceability, so that manufacturers and their customers have the reassurance of a full data trail for safety audits and compliance.

Challenges

On assembly lines working to demanding production deadlines, the need to reduce complexity while maintaining the highest possible quality control is becoming increasingly challenging. The last thing you need is multiple calibration tools and associated cabling taking up room in a working environment where space is already at a premium.

WRT new Wireless Rotary Torque Transducer

Desoutter has been working on a solution that will greatly simplify torque management, make data capture more reliable, and take quality control to a new level of efficiency. The result is our new Wireless Rotary Transducer (WRT), which offers a simpler way to achieve tool verification or calibration without the need for cabling or any software. Indeed, this little black box is all you will need to calibrate a whole range of tools, including click-wrenches, slip-wrenches, pneumatic tools, nutrunners and even Pulse tools.

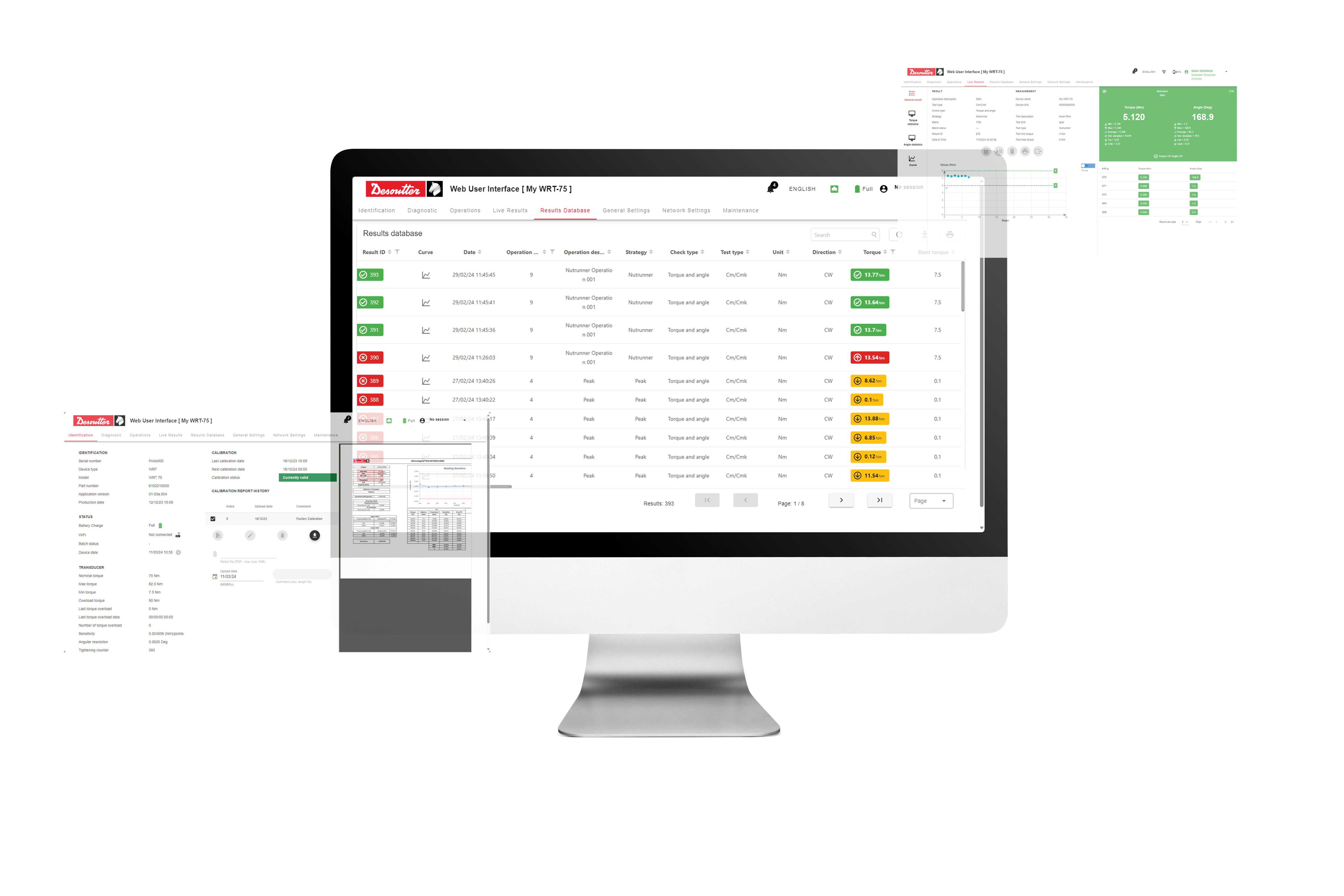

Web Interface to captures torque & angle data

Communicating via an easy-to-use web interface, the WRT captures torque & angle data along with the traceability information required for reliable quality control. Its impressive memory can store up to 50,000 results and 5,000 curves, while it delivers a torque accuracy of +/- 0.5% of the reading, giving you total peace of mind.

Calibrate the tool, check machine capability (CM / CMK)

The WRT can be used to calibrate the tool, check machine capability (CM / CMK), and undertake a short test in “Demo mode”. It is equally useful in automatic stations (including screw feeder systems), in applications where access is a challenge, and with handheld tools.

How does it work?

How does it work? Well, without giving too much away, the WRT uses magnetic ring technology and a brushless optical transmission system. This is the first time that this technology has been used for a rotary transducer, so it’s a proud moment for the Desoutter technical team whose commitment to excellence drives them to create game-changing solutions for the industry.

Acess tool data, view curves and download results in a matter of seconds

And how does all this clever technology translate into benefits for our customers? Put simply, the WRT allows quality and production managers to access tool data, view curves and download results in a matter of seconds using a device of their choice (computer, tablet or smartphone) – making tool verification and calibration so much easier. WRT guarantees that every tightening operation meets the highest standards, reducing errors, improving efficiency, and ensuring product reliability. With the WRT, manufacturers can confidently adhere to industry regulations and provide top-notch products.